Thermography

Create a Raised Effect

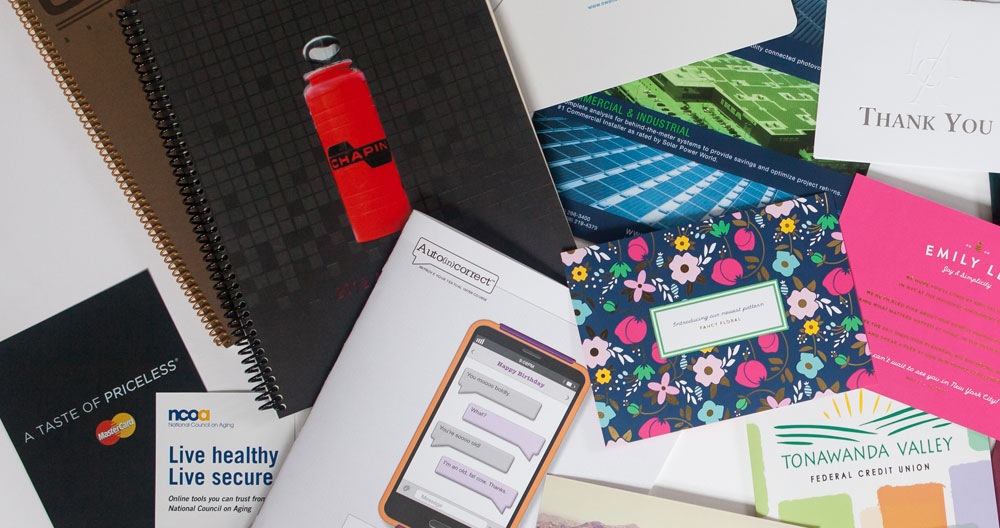

Thermography creates a raised effect on images and letters. While commonly used on business cards, letterheads and envelopes, many more creative opportunities can be considered – including greeting cards, report covers, advertising and packaging materials.

Thermography is produced using a traditional offset press. Thermography can be applied to any freshly printed sheet, whether it is single color, four-color process, or a spot varnish pattern to add texture to a previously printed piece.

With good design being the key, you can have the added attraction of dimension and brightness by using thermography. Making use of the many powders that are available which include clear, matte, pearlescent, fluorescent, and glitter, can turn any printed project into a smart, professional-looking or fun design piece.

Large solids, when thermographed, will often have an orange peel look in the finish. Thermography cannot produce a mirror-like finish that you may get in some types of UV coatings.

Here’s How the Thermography Process Works

- A printed sheet drops off the printing press onto the conveyor of the thermography machine.

- The conveyor moves the freshly printed sheet through the powder applicator, covering the entire sheet with thermography powder.

- The thermography powder attaches to the wet ink.

- The extra powder is vacuumed up and stored for re-use.

- The coated sheet passes through an oven with temperatures ranging from 900 to 1300 degrees Fahrenheit, where the powder melts and flows to create the smooth effect.

- The sheet passes through a cooling tunnel and is stacked.

Laser Safe Thermography

Traditional thermography powder can re-melt when exposed to heat, so if the thermographed letterhead is later used in a laser printer, you will want to be sure to specify “laser safe thermography.” Laser safe thermography is produced using a special powder that is melted in the thermography machine, then is cured using ultraviolet light. This type of thermography cannot re-melt and is safe to use in laser printers.

What Is the Difference Between Thermography & Engraving?

Thermography and Engraving are two unique specialty print processes that both use ink to produce raised print. However, there are some key differences between the look of each that distinguish them, and might make you wish to select one over the other depending on your project.

The Look

Thermography can look matte or shiny (glossy) depending on what type of powder is used. The appearance of thermography will depend on the ink coverage in your design. If there are mostly words or a design with thinner lines and more open space, thermography will look and feel smooth. If you have a solid area of ink coverage, thermography will look bumpy or rippled.

Engraving can use either a metallic or non-metallic ink. A metallic ink will appear shiny, especially if a process called burnishing is applied. Many times, engraving done with gold or silver ink is mistaken for foil embossing. A non-metallic ink will have a matte appearance.

The Feel

Both produce printing you can feel. Thermography feels more plasticky whereas engraving has a matte ink feel. The big difference in the feel is in the impression of printing on the paper. If you are holding a piece of paper that has been printed with engraving, and flip it over, you will see what is called the “bruise” on the back side. This is the area where the die and counter meet to press the image into the paper, leaving behind the image on the front of the paper and an impression on the back of the paper.

With thermography, the ink is raised off the sheet of paper from the top using a special powder and heat, so there is no force being used, therefore no impression into the paper. The back side of thermography will be smooth.

Security

Engraving is the print process used to print currency because it cannot be altered. The process of engraving uses a metal die and a high-pressure press to stamp the impression into the paper, infusing the ink into the fibers of the paper, which cannot then be altered. It is commonly used to produce high-level diplomas and certificates to maintain the security and integrity of these documents.

Thermography is a process that, while not easy to reproduce without the equipment and skill of a press operator, is more easily reproduced, especially as technology in some digital presses now allow for a “raised” effect to be printed digitally, mimicking thermography.

How It’s made

Engraving starts by taking the image to be printed, and etching it onto a copper die. That die is set into the press (called a diestamping or engraving press), then ink is applied to the die and the press uses a high amount of pressure to stamp the die into the sheet of paper.

Thermography is done in-line with an offset press. The offset press prints the image onto the paper, then the paper passes under a powder applicator which puts a specially formulated powder onto the ink that was just printed. The sheet of paper then passes, at very high speeds, through a heated tunnel where the heat reacts with the powder, adhering it to the ink and raising it off the paper.

Request Your Free Samples

Let us put our high-quality samples in your hands so you can see for yourself how we can help you simply add style, distinction and elegance to ALL of your printed materials!

Thank You for Finding Us

We look forward to beginning or cultivating our relationship further in the near future!